2017 2018 ISO 4

페이지 정보

Contents

- PREV2017 2018 ISO 3 22.12.21

Comment List

No comments.

R&D Introduction

scroll down

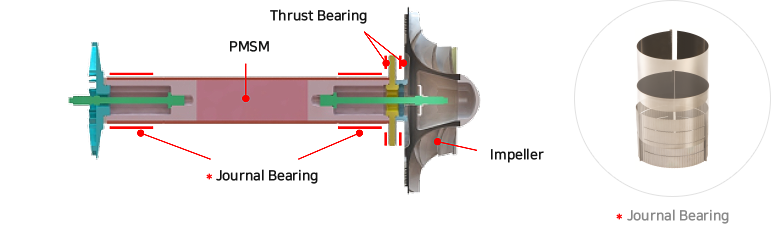

High speed permanent magnet synchronous motor at its highest efficiency (PMSM)

PM motor of MCB is optimized for high speed rotation, which provides high efficiency of 98% by minimizing the high frequency loss.

High efficiency over the entire operating range with permanent magnets Electric motor optimized for maintaining high speed rotation Rotating up to 60,000 RPM

Wide range of flow control by the inverter control Low noise below 85d / Oil free lubrication system Small heat dissipation structure compared to the output capacity

Air Bearing applied No power loss due to direct drive Optimized design for high speed rotation

| Output | 30 ~ 300Hp |

|---|---|

| Rotation Speed | 15,000 ~ 68,000rpm |

| Number of Poles | 2 |

| Insulation rating | H |

| Cooling system | Air cooling / water cooling (Different by models) |

Air bearing

Non-contact bearings that utilize fluid dynamic pressure that occurs automatically between motor and foil rotating at a high speed, provide a structure with no friction at all during the operation, which is developed with our unique technology.

A non-contact bearing, which supports the load of the rotating body by using a force of an air around the shaft rotating at a high speed, compressed by the wedge effect.

The air bearing type of mcb-Series is non-lube and non-contact, which does not use a lubrication oil, while not causing the malfunction and making the maintenance convenient due to the simple system structure. It maintains the highest efficiency by minimizing the power loss and provides a stable and long life with non-vibratory and noiseless environmentally friendly air bearings.

| Air foil Bearing | TilTing Pad Bearing | Ball Bearing | |

|---|---|---|---|

| Lubricant | Not used | In use | |

| Durability / Life | Semi-permanent | ||

| Maintenance | None | Check once every 5 years | Replace after a certain period of operation |

| Credibility | 20 | 1 | |

| System | Simple | Complicated oil system | |

| Application | Small device, ACM | Industrial device | Aviation engine, Small device |

Impeller

Impellers of mcb Series, manufactured with aerodynamic system technology, deliver highest durability due to a sophisticated manufacture process.

Optimal design with a precision processing technology Forged aluminum alloys, suitable for high speed rotation.

Minimized tolerance range with the 5-axis machining.

Verified structural stability of the impeller by the spin test at rotational speed of 120%.

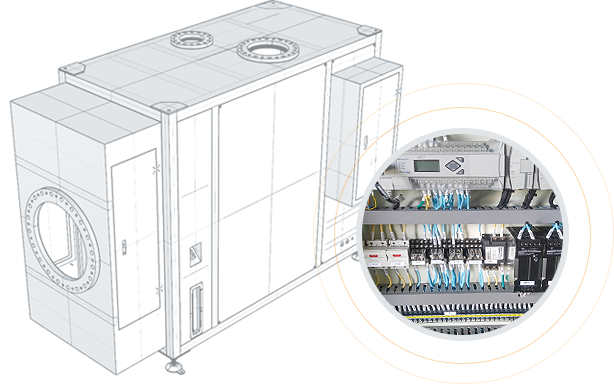

Inverter

Eliminates unnecessary energy waste by managing the rotation speed of the PMSM to control the flow rate requested by the customer.

| Output | 30kW ~ 300kW |

|---|---|

| Efficiency | 96 ~ 98% |

| Switching frequency | 8 ~ 12kHz |

| Output frequency | 800 ~ 1,200Hz |

| Voltage | 300 ~ 500V |

| Cooling method | Air cooling / water cooling (Different by models) |

Controller

Provides optimized control system for an automated operation.

Data Sheet

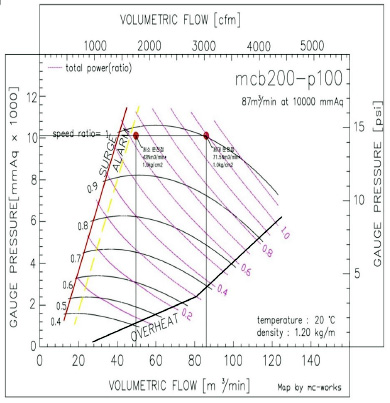

Understanding the performance curves of the TURBO BLOWER

The upper and lower limits of pressure/flow rate are applied to each model

Able to operate within the surge point and the overheat line of the performance map

Inhalation temperature; affected by the humidity

Change in flow rate at the change of discharge pressure. (If the pressure rises, the flow rate decreases; inversely proportional)

Surge is where the discharging air flows backward, causing the noise/vibration, while pressure and flow rate is fluctuating rapidly.

TURBO BLOWER Operation Mode

No comments.

Company: mc-works Co,.Ltd.

Tel: +82-31-8015-4157 Fax: +82-31-8015-4158 E-mail: meiji0813@naver.com

Address: 42, Dongtansandan 2-gil, Hwaseong-si, Gyeonggi-do, Republic of Korea